We might have to revisit the topic of quarter sawn woods and the adventures they offer to your woodworking a few hundred more times – because there’s a lot to know about this animal.

The bottom line is that quarter sawing is a technique for slicing logs, and that technique yeilds some wildly awesome and different results depending on the type of wood you’re dealing with. One such result is called “ray fleck figure,” or sometimes a more simplified term like “flecking,” “flecks,” or “rays.”

We don’t know who makes the rules on what it’s called. Once again that’s part of the adventure in navigating the tribal knowledge of hardwood lumber terminology.

So what does quarter sawing mean to you and your woodworking?

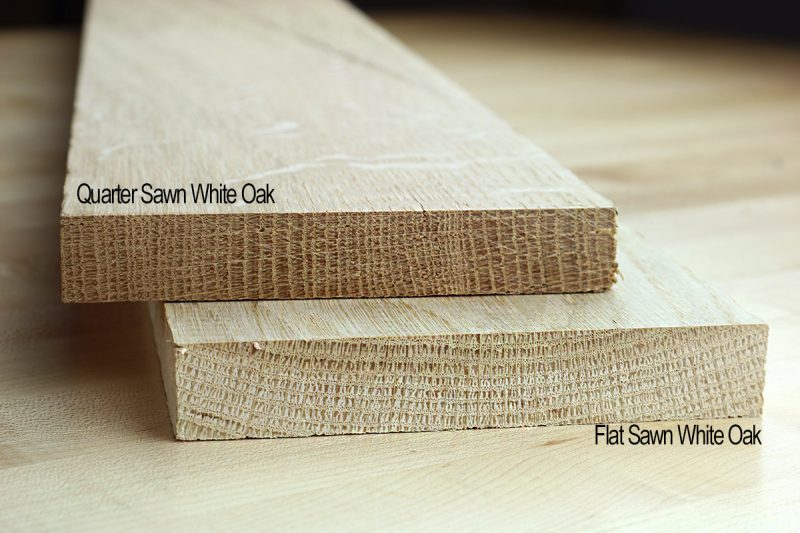

To get an idea of how to identify quarter sawn boards, check these out:

This gets interesting to answer. Most lumber sitting in the bins at a store like ours will be flat (or plain) sawn or what’s known as “mixed grain” which can have any mix of it all.

So on one hand, you get it by luck.

But some woods, such as white oak, are routinely cut, sorted, and offered separately in the different types of cuts. So in that sense, you can get quarter sawn wood as long as your lumber source offers it that way.

Yes, and you should know about them. Due to the way it’s cut, you have to deal with two things:

But tap play on this video and we’ll show you a few things about that fleck figure. Plus we’ll show you a couple of ways to make that figure look absolutely killer in your woodworking projects with a few finishing techniques.

Vice President of Operations – Woodworkers Source

We’re a family-owned lumber & woodworking supply retailer with 3 delightful stores in Arizona, and 35 friendly employees.

Mark oversees the company and creates tutorials on wood finishing and woodworking tips for hardwood lumber.

Woodworkers Source is a division of MacBeath Hardwood Co.