HOW THEY’RE MADE

– Approx 2 bdft of shedua

– Approx 1 bdft of contrasting wood for handles

– Cutting board oil + wax

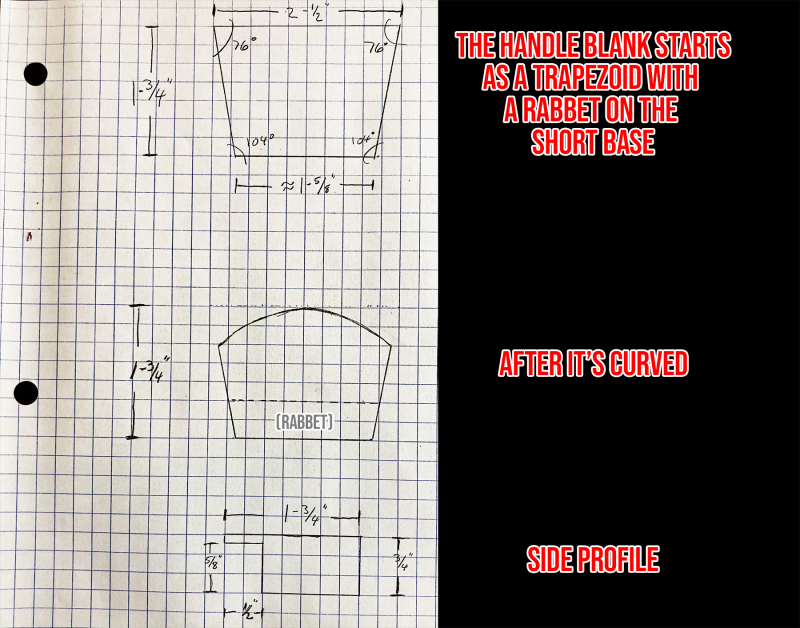

Details about sculpting the handles are below!

I like to take a longer board that’s 3/4″ thick with one straight-line-ripped edge and cross cut it to the 10″ lengths. Then rip each one to 6″ wide.

TIP: This is a trick I learned long ago from someone else who taught me that when you cross cut a board, and if you’re not paying attention to whether or not it’s backed up or supported in some way where the blade exits the board, it will most likely splinter. Doesn’t matter what kind of wood, but some are worse than others at splintering during a cross cut.

Anyway, I like the practice of cross cutting the boards to final size, then ripping each one to width. That rip removes any splintering that might have happend during the cross cut at the exit corner.

My $0.02

Just set the table saw fence at 3/8″ or so. This isn’t a critical dimension, just a dimension that would be pleasing to your eye for the width of the feet.

Then rip a 3/4″ thick board into how ever many strips are necessary to cut some 6″ long parts.

I made two trays, so I only needed 4 feet (two per tray) but ended up with more than that.

It’s easier to cut the cross-grain dadoes before giving the tray body a curve or shape.

You don’t need a dado set, just a tablesaw blade with flat-top teeth. Flat top teeth make a cleaner looking dado, but if you don’t have one it’s not a deal breaker. Use what you have.

If you don’t have a template for the curve, make one. The easiest thing to use is MDF because it’s so easy to manipulate to shape and it’s cheap. But truth be told you can use any shapeable material you’re comfortable using.

Line it up, and use a pencil to draw the line. Or use a marker if you’re using a dark wood.

Now do whatever it takes to hog off the bulk of the waste. In the video, I managed to do so with an angled cut on the table saw because the curve was so slight. If you have a bandsaw, use that. A jig saw works, too.

Attach the template and use a flush trim bit to make the curve smooth, then use a 20° bevel bit to give that edge a nice angle.

TIP: The grain orientation on these handles are cut in a way so they’re the same direction as the grain on the tray body. So when you shape the curve with a block plane, know that you’ll be working the end grain and therefore you’ll want to avoid planing off the edge. It’s awkward because the “rule” about planing a curve is that you should always plane downhill – but if you do you risk blowing out the edge if you run the plan off the workpiece. There’s no silver bullet for this, just be cautious.

I know it will test your patience, but in the long run you get a nicer result if you finish sand as much of the parts as possible before assembly. It solves the issues you’d run into to sand in tight corners after assembly.

Glue in the parts, and then scrap off glue squeeze out after about 20 minutes. Just enough so it starts to set up but not harden. That too easier to deal with than waiting until it’s dry.

Then, once it is dry, do a little touch up work to clean up the corners or for any touch up sanding that’s necessary.

To finish, apply two coats of a cutting board oil. Then follow it up with a coat of wax. The project will be food safe and look fantastic.

Vice President of Operations – Woodworkers Source

We’re a family-owned lumber & woodworking supply retailer with 3 delightful stores in Arizona, and 35 friendly employees.

Mark oversees the company and creates tutorials on wood finishing and woodworking tips for hardwood lumber.

Woodworkers Source is a division of MacBeath Hardwood Co.