Teak Paper Back Veneer Sheet - 2' x 8' Roll

SKU: 20257502$185.00 ea.

Why Choose Teak?

The luxury yacht of hardwood: teak's rich color, natural oils, durability, and workability make it the only choice for luxurious, long-lasting custom furniture that ages gracefully with minimal maintenance.

These real wood veneer sheets are composed of premium sliced hardwoods that are spliced along the edges to make the full width; splicing is also done in a book matched pattern that's attractive and helps hide the splicing seam. The sheets use full-length slices so there are no splices to make the length. The 10 mil (10 thousandths) thickness paper backing allows the sheet to bend, flex, and work with curves and shapes without splitting. Apply paper back veneers with contact adhesive to make panels of large projects: conference tables, desks, doors, cabinet doors, coffee tables, etc.

| Thickness | 1/42" (≈ 1/42" approx) |

| Width | 24" |

| Length | 8' |

| Grade | Architectural grade paper back veneer is cut from the cleanest and most attractive logs; all sheets are sanded smooth to 220 grit |

| Quantity | One sheet has 16 square feet |

3.33

lbs /Bd. Ft.Wood Texture

Ease of Finishing

Dark golden yellow turning dark brown with age.

This tree may reach 130-150 feet in height with clear boles to 80-90 feet. Trunk diameters usually 3-5 feet; older trees fluted and buttressed.

Burma teak, Rosawa, Djati, Sagon, Genuine teak, Sagwan, Gia thi, Tadi

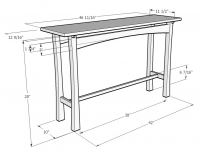

Furniture, flooring, carving, cabinets, interior millwork, turnery, shipbuilding, and exterior and marine applications.

Teak Veneer

The Joys of Building with Great Woods

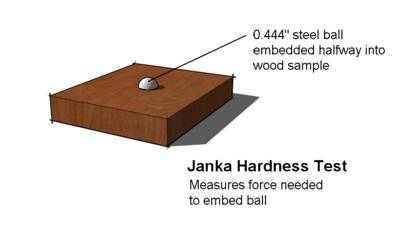

Understanding hardwood lumber starts right here with these wacky fractions.

If you're expecting perfect clear lumber 100% of the time, you're in for a surprise. Here's a summary of the hardwood lumber grades and what to expect from them.

Board feet isn't your everyday kind of math, but these three simple steps make it easy to figure out your project.

Here's a handy (and free) Excel worksheet that helps you estimate the lumber needs for your project.

Are woods poisonous? Hazardous to use in cutting boards or baby cribs? Find out here.

Wood is like a sponge, and it's always in a state of absorbing or releasing moisture to stay equalized with its environment. The problem with that is it also swells and shrinks. Here's what you need to know to protect your project.