$17.00 ea.

for 20 or more mix/match

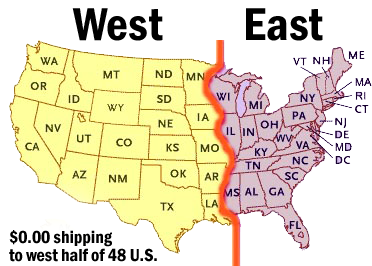

(48 U.S. Ground)

Why Choose Soft Maple?

Resembles Hard Maple being closed-grained but much softer. Easily worked. Turns and planes well. Does not require fillers to achieve a glass smooth finish. Accepts finish and paint well

Get ready to work with the finest wood squares you've ever seen, they're ready to be turned into whatever you can imagine, such as furniture parts, table legs, small accessories, handles, artwork and other fine woodworking projects.

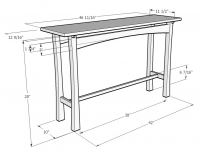

| Thickness | 1-3/4" (≈ 1-3/4" approx) |

| Width | 1-3/4" |

| Length | 30" |

| Grade | Kiln dried, clear |

Woodworkers Also Recommend These

2.63

lbs /Bd. Ft.Wood Texture

Ease of Finishing

Cream white to reddish brown.

A popular, fast growing decorative tree. Matures to about 60-90 feet in height and 30" in diameter.

Carolina red maple, Drummond red maple, Maple, Red maple, Scarlet maple, Soft maple, Swamp maple, Water maple

Furniture, cabinets, a good general purpose hardwood

The Joys of Building with Great Woods

Understanding hardwood lumber starts right here with these wacky fractions.

If you're expecting perfect clear lumber 100% of the time, you're in for a surprise. Here's a summary of the hardwood lumber grades and what to expect from them.

Board feet isn't your everyday kind of math, but these three simple steps make it easy to figure out your project.

Here's a handy (and free) Excel worksheet that helps you estimate the lumber needs for your project.

Are woods poisonous? Hazardous to use in cutting boards or baby cribs? Find out here.

Wood is like a sponge, and it's always in a state of absorbing or releasing moisture to stay equalized with its environment. The problem with that is it also swells and shrinks. Here's what you need to know to protect your project.