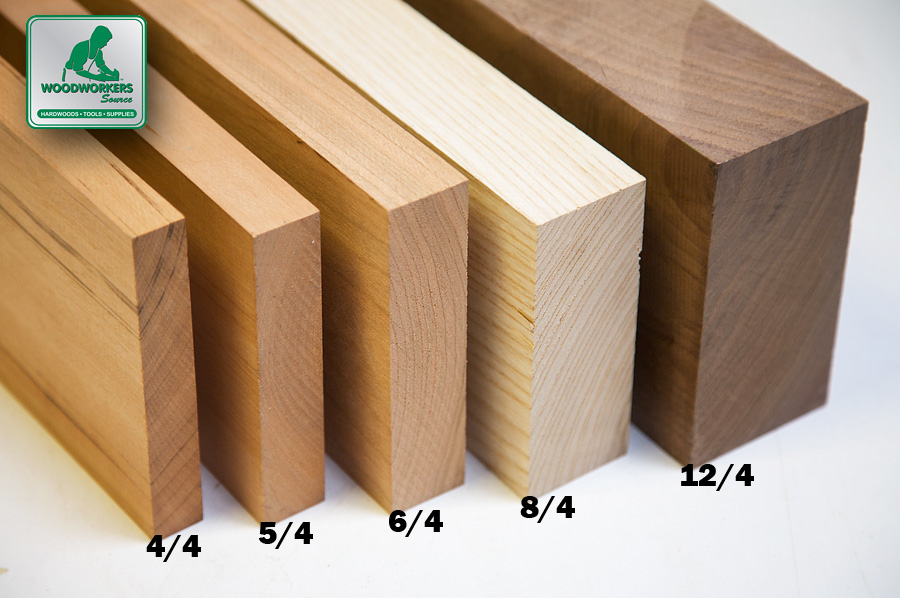

Hardwood lumber comes in thicknesses measured in quarters of an inch. 1″ lumber is called 4/4 (four quarters). 2″ lumber is called 8/4 (eight quarters). Here’s how they compare.

This is a fraction that tells you approximately how thick the lumber is.

It’s more of a name than it is a precise measurement because there’s a lot more to the story.

While you might be used to seeing sizes like 1×6 or 2×8 in lumberyards for softwoods (fir, pine, cedar, etc.), the hardwood industry takes a different approach.

That’s because the primary users of hardwoods (red oak, cherry, maple, etc.) build custom or made-to-fit products – like furniture and cabinetry – where uniform sizes in the raw material is unnecessary and more troublesome. For example, there’s no standard size for kitchen tables, you can make one any size you want. So sawmills cut hardwood logs to get the best yield from a log, which means all boards will be various in width rather than the same width. If sawmills were to cut logs to specific sizes or uniform widths, that process would incur more waste and require more labor. Therefore the resulting boards would cost you more money. Who wants that?

Softwoods that get sold in “standard” sizes like 1×6 and 2×8 are cut for particular applications that require those sizes. In building construction you’ll find standard and uniform sizes from building to building. Door jambs and wall studs for example.

So, the hardwood industry standard for indicating the size starts with lumber thickness, and it’s expressed as a fraction: 4/4, 5/4, 6/4, 8/4 and so on.

This system of naming lumber thickness by quarters was established by the National Hardwood Lumber Association. The organization was founded in 1898 to establish a uniform system of grading rules for the measurement and inspection of hardwood lumber.

With rough lumber, it’s hard to see the grain and the boards are frequently slightly cupped or warped from the drying process. Surfacing fixes both of these, but it does remove thickness.

If we were talking you’d hear me say it as “four quarters,” which is short for four quarters of an inch. If you’re pretty snappy with numbers, you’ve already put together that 4/4 is probably one inch.

4/4 means approximately 1″ thick

5/4 means approximately 1-1/4″ thick

6/4 means approximately 1-1/2″ thick

8/4 means approximately 2″ thick

12/4 means approximately 3″ thick

But there’s more.

To know what the actual measured thickness is, you need one more identifier such as S2S or RGH. S2S means “surfaced two sides,” and RGH means “rough” and they describe the stage the lumber is in, surfaced or rough. But all lumber starts out rough.

A saw that cuts lumber from a log is very large and aggressive, so the resulting lumber is known as “rough sawn” and the surfaces of the boards are . . . yes, rough and inconsistent. This lumber needs to be planed smooth and flat before being sized for the project at hand.

Enter S2S. Lumber that is S2S was rough at one time, but now it’s been planed smooth and flat. Naturally, that process removes some thickness and answers the age old question, “Why isn’t 4/4 lumber a full one inch thick?”

Actual measured thickness on 4/4 lumber that’s S2S is 13/16″. According to the NHLA rules, 13/16″ is the standard acceptable thickness of surfaced 4/4 lumber. (Note: you can view the current edition of the NHLA rule book here.)

Rough lumber needs to be dressed with a planer and/or jointer and this is where a lumber dealer like Woodworkers Source has to make a tough decision. Have the lumber surfaced smooth and clean, or sell it rough? There are benefits to both, but it’s impractical to stock both.

Rough Sawn Lumber (RGH)

Pros

– Usually costs less

– Most of the time you can yield more thickness than the standard surfaced thickness

Cons

– Difficult to inspect grain, figure, and color

– Often cupped or distorted from the drying process

– Requires time and labor to plane and flatten before moving on to final sizing

– Heavier, costs more per board foot to ship

Surfaced Lumber (S2S)

Pros

– Usually easier for the less-equipped woodworker to use

– Easy to see the grain, figure and color

– Uniform in thickness

– Lighter, costs less per board foot to ship

Cons

– Less control over final thickness

– Surfacing adds cost

– Less margin for dealing with cupping and warping

One difference between rough and surfaced lumber might not be very obvious, which is the weight. It’s commonly thought that rough lumber is cheaper because it doesn’t have the added cost of surfacing. But that’s not the end of the story. While there is a charge for surfacing lumber, surfaced lumber weighs a lot less, and this plays a big role when we transport truckloads or container loads from suppliers.

For example, a flat bed truck will haul 45,000 lbs. The cost to move that load doesn’t change if load of lumber is rough or surfaced – 45,000 lbs is 45,000 lbs. But what does change is how much lumber will fit on the truck. You can fit about 11,000 board feet of rough lumber or 14,000 board feet of surfaced lumber. In the end, it just makes more sense to pay the wholesaler the marginal fee for surfacing (which is about $0.10 per board foot) in favor of fitting more lumber on the truck or container.

Therefore we’ve decided to stock surfaced lumber.

Here are pictures of each lumber thickness to help you out:

Vice President of Operations – Woodworkers Source

We’re a family-owned lumber & woodworking supply retailer with 3 delightful stores in Arizona, and 35 friendly employees.

Mark oversees the company and creates tutorials on wood finishing and woodworking tips for hardwood lumber.

Woodworkers Source is a division of MacBeath Hardwood Co.