Look close. This piece of walnut is not only finished with a clear lacquer but the light colored sapwood has been evened out to nearly match the heartwood. Woodworking with walnut today means dealing with the sapwood. Here are 3 ways.

Few people approve of pale sapwood in their walnut lumber, but in the words of Jim, a salesman at one of our faithful walnut suppliers back east, “When people ask me for a 100% heartwood face in walnut, I just tell them they’re dreaming.” You may be tired of hearing that sapwood isn’t considered a defect when it comes to grading lumber, however it is an industry fact. Lumber grade is a mathematical computation of the amount of clear wood in a board – so says the National Hardwood Lumber Association, the organization responsible for defining the rules of the lumber trade.

“But it’s a defect to me,” says the woodworker.

So what’s a woodworker to do? Fortunately, lumber producers separate their walnut inventory not just by grade but also by color. The good news is 100% heartwood walnut can be had; the bad news is few can afford it. For the most part, about the best balance between color, cost, availability is called 90/70 heart: that means 90% heartwood on the face, 70% heartwood on the back. Remember, lumber has two broad sides, a face and a back, and when building furniture and cabinetry, only one side is displayed in the final product.

Sure, it’s possible to find some 100% heartwood boards from time to time, but on a consistent basis and in large quantities? Not really. And therefore, when you visit your nearest lumber supplier, you’ll never have a perfect pile of full brown walnut to select from. Full heartwood boards are the exception to the rule, so it’s time to look at how woodworkers are using walnut in today’s woodworking.

You’ll find a number of discussions and blogs about this topic, and a good one in particular is this found at Lumber Jocks, www.lumberjocks.com/topics/10565, which discusses three ways woodworkers overcome sapwood.

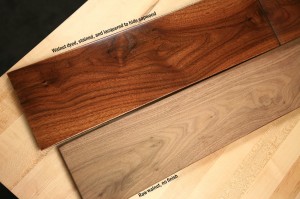

Two walnut boards compared. Bottom is raw, top is dyed, stained, and finished to hide the sapwood. Can you tell where the sapwood and heartwood meet? Look closely.

Those first two are straightforward.

Dyeing and staining needs some explanation, though. Since you’re not going to be able to go the woodworking store and buy a bottle of Sapwood Hider right off the shelf – alas, no such miracle exists – there are a couple of steps involved, but they’re easy.

For this method, we’re specifically talking about dye and there are a number of dyes on the market, usually mixed with water or denatured alcohol. Dye is different from stain, as dye doesn’t obscure the grain, which is pretty important when using walnut.

The basics:

1. Apply a very diluted dye in a color of your choice to the entire piece, heartwood and sapwood. Two nice choices could be Behlen Solar-Lux™ Medium Brown Walnut color or American Walnut color. Solar-Lux™ is UV resistant and fade resistant, which is great because when walnut is left natural, it eventually turns very tan. There are several techniques to apply the dye (which we’ll cover in another post), but in general you’ll want to dilute it by maybe 50%, then apply it in 2 or 3 coats rather than one full-strength coat because it’s easier to get a better result that way.

2. Seal the wood with a light coat of sanding sealer or shellac. This needs to be thin to allow for the next step to have some effect. Spray it or pad it on.

3. Apply an oil-based gel stain on top of the sealer. Wipe it on, wipe it off. When you wipe it off, use a bit of an artist’s hand – that is, don’t wipe too hard or too soft. You want to leave a light coat of stain right on top of the sealer while also lodging pigment into the pores. In the end you get a gorgeous consistent color across the board.

4. Apply your clear finish of choice. Varnish, lacquer, etc.

It should go without saying that you should always test your dye process on a few test pieces before committing the dye to your final product. You’ll need to test different dilution ratios of your dye before you get the color you want.

Dyeing walnut is not very difficult, but it will take some time. However, you’ll greatly increase your yield of wood and you’ll make the beautiful walnut color last much, much longer than you would if if were to leave the wood natural.

In this dyed and stained walnut board, you get a nice, dark chocolate color that will last a long, long time. The processed used also blends the pale sapwood so it’s not too different from the heartwood.

Vice President of Operations – Woodworkers Source

We’re a family-owned lumber & woodworking supply retailer with 3 delightful stores in Arizona, and 35 friendly employees.

Mark oversees the company and creates tutorials on wood finishing and woodworking tips for hardwood lumber.

Woodworkers Source is a division of MacBeath Hardwood Co.