It all comes from the same tree: hard maple, rock maple, sugar maple, brown maple, white maple. The acer saccharum to be most specific.

That species name, saccharum, is Latin for sugar.

You might be drawing the correct conclusion about now that that the very tree that gets harvested for beautiful hard maple lumber is the same one that produces the finest maple syrup that take ordinary Sunday morning pancakes to a whole new level of scrumptious mouthwatering joy.

I didn’t hear your stomach growl, did I?

While the wood carries many interchangeable names, the woodworker most often cares about the two distinct appearances of the wood.

The heartwood, like most hardwoods, is much darker than the outer sapwood. With hard maple, it’s the clear white sapwood that’s in high demand. Whereas it’s the heartwood of woods like cherry and walnut that are the envy of American woodworkers.

In general, the industry identifies hard maple in three ways:

“Selected” hard maple can be a little deceptive. In this case, we’re not talking about the grade “select” but whether or not the wood has been sorted for color: such as “white boards selected.” We stock this as Hard White Maple.

It’s a process that usually happens at the sawmill rather than further down the distribution chain. For instance, we’ll get a nice list of current lumber offerings from one our trusty lumber sources. And on that list we’ll see availability of some “4/4 Hard White Maple” and then perhaps a line with “4/4 Hard Maple (UNSEL)” and another with “4/4 Hard Brown Maple.”

Unselected (UNSEL) maple means no white maple has been pulled out of the load. Some boards are white, some are brown, some have both.

You probably won’t find unselected maple at a retail distributor because the non-selection is descriptive of a full load or “batch” of lumber, not individual pieces.

However, brown hard maple is what’s remaining after a load has been sorted and selected for white. We stock this and call it Country Hard Maple. The color variety makes it good for rustic looking projects. It’s also called brown hard maple for obvious reasons.

Still hard maple’s major claim is its virtually pure white color with unmatchable combination of strength, beauty, and price.

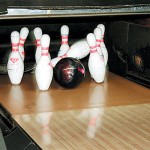

Hard maple is the only choice if you're building a bowling alley or something you'll be throwing 12-pound balls at

Because it’s durable and strong, you’ll see hard maple used for floors, butcher blocks, baseball bats and bowling lanes. And because it’s good looking you’ll see hard maple used for cabinetry, furniture, molding/trim and all types of custom woodwork. And because it’s reasonably priced, you’ll be able to use it in your shop jigs and tool parts that need to be strong and hardy; like vise jaws, clamp blocks, home made miter slot slides, etc.

Between the variety of uses for the lumber as well as the popularity of maple syrup, the acer saccharum tree is a commercially important one in North America. Want to know how much hard maple lumber was produced in 2006? 514,000,000 board feet, making it the 4th most produced lumber in the United States (behind red oak, white oak, and yellow poplar).

Try Hard Maple Today

Vice President of Operations – Woodworkers Source

We’re a family-owned lumber & woodworking supply retailer with 3 delightful stores in Arizona, and 35 friendly employees.

Mark oversees the company and creates tutorials on wood finishing and woodworking tips for hardwood lumber.

Woodworkers Source is a division of MacBeath Hardwood Co.